Cemented carbide CNC end mill

Short Description:

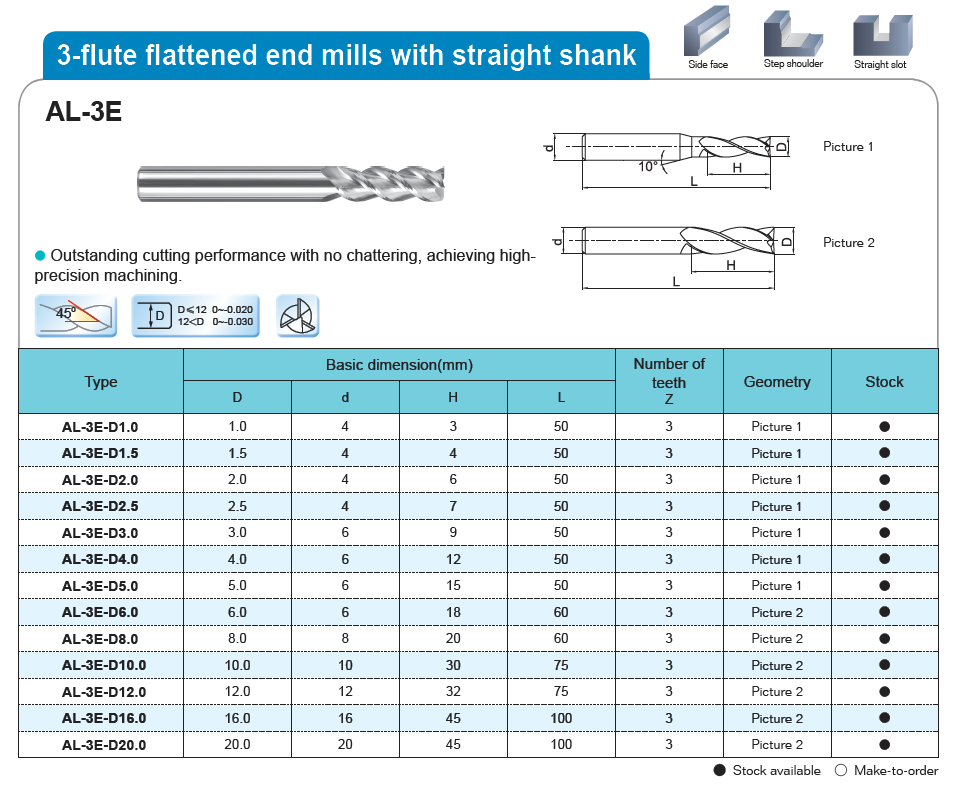

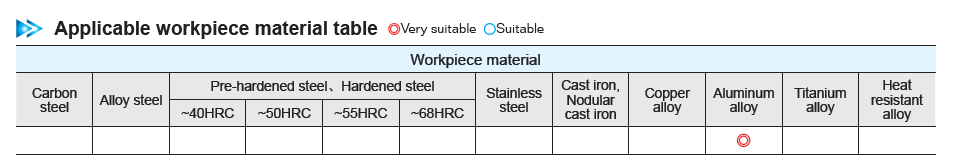

AL series 3-flute flattened end mills with straight shank end mill very suitable for AL machining.

We have extensive practical experience in this field and we can offer you almost types of solid carbide end mills.

AL series Introduction

AL series end mills for AL machining.AL series end mills are high performance cutting tools designed for milling applications. They are designed to efficiently remove material from workpieces and provide excellent surface finish and dimensional accuracy. AL series end mills are constructed of high quality materials such as solid carbide or high speed steel for durability and long life. These end mills have precision ground cutting edges and come in a variety of geometries such as square, ball nose, corner radius and roughing profiles. The flute design of the AL series end mills is optimized to provide efficient chip evacuation, prevent chip buildup and reduce heat generation during machining. This helps extend tool life and maintain consistent cutting performance. Flute configurations may vary, including two, three or four flute designs, depending on specific machining requirements. The AL series end mills are available in a variety of sizes, diameters and lengths to suit different machining tasks and workpiece materials. They are commonly used in a variety of industries including aerospace, automotive, mold making, and general machining applications. Overall, the AL series end mills are reliable and versatile cutting tools that provide high cutting performance, precision and durability for a variety of milling operations.

Excellent tool surface quality and good chips evacuation improve the cutting conditions and greatly extend tool life.

Chip pocket with unique shape exerts excellent performances even in slot and cavity machining.

Sharp cutting edge and large helical angle design effectively prevent built-up edge.

Anti-vibration design of whole edge can suppress the chattering during machining and improve surface quality.

Tool type:AL-3E-D6.0 Dimensions:Ø6.0mm

Workpiece material:LC4

Rotating speed:13000r/min (250m/min)

Feed speed:1950mm/min (0.15mm/r)

Axial cutting depth:ap=9.0mm

Radial cutting depth:ae=1.0mm

Cutting style:Complicated cavity machining

Cooling system:air blow

Machine tool: MIKRON UCP 1000

Parameter

Application

FAQ

According to the shape we have so many types , such as flattened end mill, radius end mill, ball nose end mill, high-feed-rate end mill, long neck end mill, tiny head end mill and so on.

The main different is processing requirements: end mills are for milling, while drill bits are for drilling and reaming. Although in some cases, the milling cutter can also drilling, but it is not the mainstream.

If the type we have in stock, any quantity will be OK.

Yes, we can customize for you as your requirements.

First, the workpiece material.

Second, the shape and dimension details:shank diameter, flute diameter, flute length and total length, the number of the teeth.

Third, if you need customized, offer us the drawing will be better.